|

Click to listen to this article

|

By Dave Alexander, Publisher

If the thought of making moonshine in your backyard makes you read this article, then chalk one up for salacious headlines. We’re not going to give you any hooch recipes here, but if you use drip to irrigate, or plan to in the future, then read on.

Every year, millions of pounds of drip tape are pulled from the ground. Rather than using the non-sustainable method of dumping it on the “north forty,” growers have limited options to dispose of the old tape. Most landfills won’t accept the tape, or will only take restricted amounts. Burning plastic releases dangerous gasses and is illegal in most states. There are companies in the Treasure Valley and Washington, such as Clearwater Supply, that will collect old drip tape and ship it out for recycling the plastic. Currently, this is the best option, but what if old tape could be converted to fuel for tractors on the farm?

Pyrolysis

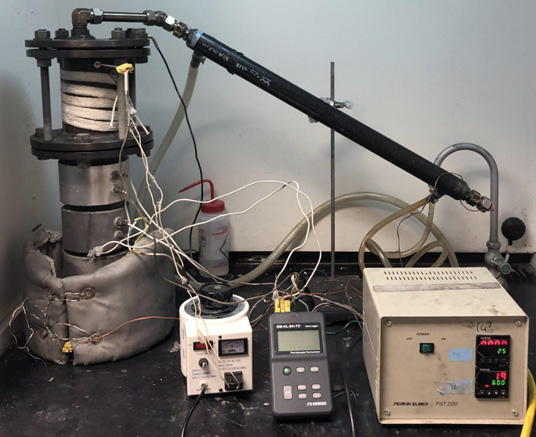

Oregon State University (OSU) has already built a small-scale, 1kg reactor (or still, as we like to say) to turn ag plastics into tractor-ready red diesel using pyrolysis. Pyrolysis, in this case, is the heating of plastic to extremely high temperatures to break it down and vaporize it. The vapor is then re-condensed into diesel. One kilogram of drip tape yields one liter of fuel.

Does it make sense to build one of these open-source reactors on your farm? The construction only takes three components, and they are simple to operate and only need minimal maintenance. The idea is intriguing, but in reality, it will all come down to return on investment for growers. OSU will be working on ROI numbers soon.

Perhaps a better solution is placing a large-scale commercial unit nearby. PDO Tech has a 500kg unit available that may be a solution for a grower collective or a single grower that uses a lot of tape. The company operates a reactor currently in western Oregon, where a lot of tape gets sent for recycling.

Sustainability

Vegetable processors and large retailers are already pushing for sustainability and zero-carbon footprint farms. If you are not currently recycling drip tape, it’s time to do it on your own before you are forced to. Plus, it’s the right thing to do and it opens up a lot of moonshine jokes.

Denise Anderson, CEO of Clearwater Supply, is looking forward to plastic-to-fuel technology, but she also knows there is much work ahead to get there.

“As we look forward to the future, envisioning recycled products being transformed into fuel represents a beacon of innovation and sustainability,” Anderson said. “Until such technology becomes both feasible and readily available, we must persist with other sustainable methods, ensuring our commitment to the environment remains steadfast and adaptable.”

OSU estimates that there are 1.6 million pounds of drip tape used per year in the Treasure Valley alone. While that might sound like an immense amount of tape to get rid of, the plus side of this is that’s over 191,000 gallons of potential diesel fuel.

Resources:

Clearwater Supply: cwsupply.com

PDO Tech: pdotech.com

Oregon State University: Search “OSU plastic to fuel” on YouTube