The U.S. Environmental Protection Agency (EPA) is issuing a final cancellation order for Corteva’s chlorpyrifos product “Dursban 50W in Water Soluble Packets” and three Gharda chlorpyrifos products, and an amendment to the existing stocks provisions for two Liberty and three Winfield chlorpyrifos end-use products. The Agency has also updated the frequently asked questions about chlorpyrifos on its website.

Author: Brian

-

University of Idaho Opens New Ag Facility

The University of Idaho’s College of Agricultural and Life Sciences (CALS) has opened a new laboratory at its Parma Research and Extension Center. The 9,600-square-foot Idaho Center for Plant and Soil Health contains laboratory space for research in nematology, pomology, plant pathology and microbiology.

CALS launched a campaign to construct the $12.1 million facility in 2019. Construction was funded by $3 million in donations from agricultural stakeholders, in addition to investments from the university and the state of Idaho.

-

British Launch National Carrot Day

The British carrot industry will celebrate its first annual National Carrot Day on Oct. 3, 2024. On this day, people will be encouraged to buy, eat and promote carrots.

The British Carrot Growers Association established the special day in an effort to celebrate the carrot as the UK’s most popular root vegetable and to communicate the challenges of growing carrots, including high disease susceptibility, high input costs and low sales prices.

The U.S. already recognizes International Carrot Day on April 4. But because this is out of season for the UK crop, Britain’s carrot growers decided to have their own special day on Oct. 3 during their peak harvest time.

-

Equipped for Change

By Wayne DeCou, Director of Equipment & Engineered Solutions, Volm Companies

The carrot industry is facing a rapidly changing landscape. From sustainability efforts to retailer requirements, the pressures come in many forms. But, as the old saying goes, every challenge is an opportunity. And there are many incredible opportunities with the exciting innovations that are emerging in the industry.

During Volm’s 70-year history, the company has seen its fair share of change. But the advancements happening now are truly unique. As a total solutions partner, we have always understood that we have to think far beyond our packaging. Because of this, we always look at how our equipment can help our customers, particularly when it comes to reducing our environmental impact. From washing, grading and weighing to bagging, baling and palletizing, choosing the right equipment is just as important when it comes to dealing with modern-day pressures.

The mud tower is part of Volm’s water recycling system designed to eliminate debris, remove soil content and reduce contaminants without using chemicals. Water Recycling

The carrot industry is experiencing these pressures directly. Water consumption, for example, is an area where many sheds are facing tightening government restrictions and, depending on the jurisdiction, punishing fines. But state-of-the-art technological solutions are keeping facilities ahead of the curve, reducing water volume while improving wastewater quality. These improvements have allowed growers to drive down costs, reduce unnecessary waste and remain in compliance of regulatory requirements for wastewater discharge.

Volm’s latest water recycling system, through our exclusive partnership with Wyma, has been a game changer for the carrot industry. This new system has a small footprint with a big impact and offers a chemical-free solution that eliminates debris, removes soil content and reduces contaminants such as E-coli, nitrates, phosphorus, biochemical oxygen demand, chemical oxygen demand and carbonaceous biochemical oxygen demand.

In stage one, dirty water is pumped from a tank to a micron filter, where filtered solids such as organic fibers, sand and produce are extracted. Pumps send the filtered water back to the process line for recycling, or to the next stage of water treatment, the mud tower. In stage two, fine soils such as silt settle in the mud tower as the water flows across its length. Clarified water then exits the tower via the overflow. Settleable solids are extracted from the base of the tower automatically. These extracted solids can be conveyed or deposited directly into waste bins. The final stage of processing takes place in the ElectroClear system. Here, water is treated to a high level of clarity with no need for added chemicals.

Facilities that have recently implemented this system have reaped immediate rewards. Daily freshwater consumption at one shed plummeted by 75 percent. Another facility was facing limited access to a freshwater supply and would not have been able to have a high-capacity wash line without the use of water recycling to subsidize its operation and overall consumption. These are tremendous benefits that will continue to pay off both financially and environmentally for years to come.

A Volmpack wash line can help carrot facilities use less water and be more sustainable. Sorting

Sorting is another area that has seen tremendous strides in technological advancements. To step up our carrot sorting and grading capabilities, Volm, in partnership with Visar, recently rolled out infrared technology as part of our optical sorter. Using 360-degree optical cameras, this sorter simultaneously sizes and grades with extreme accuracy. The latest edition of the infrared technology paired with white LED lighting helps to increase the detection of difficult-to-see defects such as rot and mouse damage. To complement the addition of this technology, the number of outputs on the machine recently increased to 16. Continuous software enhancements have also improved the sorting accuracy and efficiency. These developments have had a tremendous impact on capacity, throughput and being able to sort into different categories. All of these improvements have decreased overhead, increased profits, reduced waste and improved quality.

Palletizing

In palletizing, the headwinds have also been changing. Here, many growers and packers are facing tighter pallet requirements from retailers who are increasingly standardizing their operations. These new requirements are intended to boost efficiency and improve operations – all worthwhile causes that, nonetheless, require more compliance when it comes to pallets. Many conventional palletizing solutions are capable of delivering a high quality stack. These include our VST series of palletizers, which can help sheds easily conform to emerging retail requirements.

Partnered with 360-degree cameras and white LED lighting, the infrared technology utilized in Volm’s optical sorter increases the detection of difficult-to-see defects such as rot and mouse damage. Packaging

Finally, when it comes to packaging, Volm truly believes that innovation must continue to be the way forward. The poly bags we offer for carrots help to lock in moisture and prevent unnecessary food waste. They are fully recyclable. And significantly, as they relate to “forever chemicals,” they’re also PFAs-compliant.

While we remain committed to investing in new packaging solutions, we must also be mindful of the costly realities of doing business. Especially as we continue to feel the lingering impacts from global inflation, we believe in making every possible effort to keep costs down. Those efforts include leveraging strategic partnerships, sourcing competitively and ensuring that our packaging facilities are run as efficiently as possible. Pennies add up to dollars, and those dollars help provide the best value to customers. Staying competitive must remain a priority for everyone.

From packaging to equipment, all of these developments make it an exciting time for the carrot industry. Traditionally, automation has always been touted as a successful method of dealing with costly labor restraints. But as we’re seeing more and more, it is proving to be a highly effective strategy for prioritizing sustainability, reducing waste and meeting shifts in retailer requirements. With this progress in mind, we look forward to continuing to meet the demands facing the carrot industry – challenges, opportunities and all.

-

North Carolina to Host International Carrot Conference

North Carolina State University will host the 41st International Carrot Conference in Raleigh, North Carolina, July 8-10. This is the first time the conference will be held in North Carolina.

The International Carrot Conference is held every 18 to 24 months and aims to bring together growers, packers, shippers, seed producers, breeders, researchers, students and anyone else interested in the carrot industry.

The conference will kick off with presentations on pest and disease management, genetics/breeding, production and marketing. The final day of the conference includes a field trial showcasing current and emerging carrot cultivars and an Alternaria disease trial.

Register for the conference at www.internationalcarrots.org.

-

USDA Displays Diversity

Photos courtesy Kevser Ozel, University of Wisconsin

The 2024 USDA carrot hybrid trial illustrated the broad range of possible options available to growers. The trial, planted at the University of California Desert Research and Extension Center in El Centro, California, in mid-October 2023, featured 76 baby carrots, 87 cello types and 90 novelty types of different shapes and colors.

Colorful novelty carrots caught the eye of carrot fans and scientists viewing the USDA carrot hybrid trial. Following a relatively normal growing season, carrots from each entry were dug and displayed with tops attached shortly before a field day in early March. The approximately 50 seed company reps, carrot growers, researchers and students in attendance scored entries for traits such as uniformity, shape, color, size and percentage of marketable roots.

The trial included the Oxheart cultivar from the USDA germplasm collection. Many hybrids performed well during the season; however, sprangling was higher than usual this year, according to Tom Horejsi with the USDA-ARS, who helps set up the trial.

The incidence of sprangling, or forking, was higher than usual in the trial this year. The annual trial has been taking place since the late 1960s.

Carrots in the trial were laid out for scoring. -

Is a Backyard “Still” in Your Future? Recycling Drip Tape

By Dave Alexander, Publisher

If the thought of making moonshine in your backyard makes you read this article, then chalk one up for salacious headlines. We’re not going to give you any hooch recipes here, but if you use drip to irrigate, or plan to in the future, then read on.

Every year, millions of pounds of drip tape are pulled from the ground. Rather than using the non-sustainable method of dumping it on the “north forty,” growers have limited options to dispose of the old tape. Most landfills won’t accept the tape, or will only take restricted amounts. Burning plastic releases dangerous gasses and is illegal in most states. There are companies in the Treasure Valley and Washington, such as Clearwater Supply, that will collect old drip tape and ship it out for recycling the plastic. Currently, this is the best option, but what if old tape could be converted to fuel for tractors on the farm?

Pyrolysis

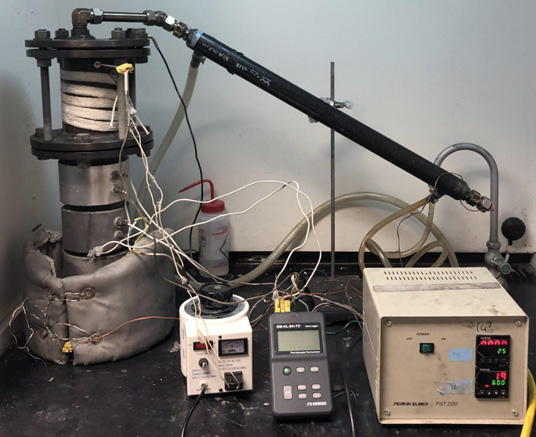

Oregon State University (OSU) has already built a small-scale, 1kg reactor (or still, as we like to say) to turn ag plastics into tractor-ready red diesel using pyrolysis. Pyrolysis, in this case, is the heating of plastic to extremely high temperatures to break it down and vaporize it. The vapor is then re-condensed into diesel. One kilogram of drip tape yields one liter of fuel.

Does it make sense to build one of these open-source reactors on your farm? The construction only takes three components, and they are simple to operate and only need minimal maintenance. The idea is intriguing, but in reality, it will all come down to return on investment for growers. OSU will be working on ROI numbers soon.

Perhaps a better solution is placing a large-scale commercial unit nearby. PDO Tech has a 500kg unit available that may be a solution for a grower collective or a single grower that uses a lot of tape. The company operates a reactor currently in western Oregon, where a lot of tape gets sent for recycling.

Sustainability

Vegetable processors and large retailers are already pushing for sustainability and zero-carbon footprint farms. If you are not currently recycling drip tape, it’s time to do it on your own before you are forced to. Plus, it’s the right thing to do and it opens up a lot of moonshine jokes.

Denise Anderson, CEO of Clearwater Supply, is looking forward to plastic-to-fuel technology, but she also knows there is much work ahead to get there.

“As we look forward to the future, envisioning recycled products being transformed into fuel represents a beacon of innovation and sustainability,” Anderson said. “Until such technology becomes both feasible and readily available, we must persist with other sustainable methods, ensuring our commitment to the environment remains steadfast and adaptable.”

OSU estimates that there are 1.6 million pounds of drip tape used per year in the Treasure Valley alone. While that might sound like an immense amount of tape to get rid of, the plus side of this is that’s over 191,000 gallons of potential diesel fuel.

Resources:

Clearwater Supply: cwsupply.com

PDO Tech: pdotech.com

Oregon State University: Search “OSU plastic to fuel” on YouTube

Marina Denny with Oregon State University is looking into building a small demonstration reactor that will recycle drip tape into red diesel at the OSU Extension Center in Ontario, Ore. -

Harvest Essentials 2024

Dewulf

Premium Reversible Cutter Set

dewulfgroup.com

Along with the second generation of its ZKIV four-row self-propelled top-lifting harvester,

Dewulf introduced an updated cutter set in 2023. The six-cutter set combines capacity and unparalleled speed with the highest possible respect for the end product throughout the harvesting process. In addition, the set is less prone to wear and tear, as Dewulf fabricates the cutters with a new type of highly wear-resistant material. Moreover, the blades of the cutter sets are reversible, extending their life. If the front part is worn out, users can effortlessly invert the cutting bars to start using another zone of the cutting bars. This cutter set is now also available on the ZKII and ZKIII top lifters.

Kerian Machines

Speed Sizer

kerian.com

The Kerian Speed Sizer sorts carrots by size accurately and consistently. The constantly rotating rollers help the turning flaps align the carrots with the rollers so that the carrots (with or without tops) are consistently sorted by diameter. The sizer is proven in use for fresh carrots, baby carrots and processing lines.

Univerco

G-Force

univerco.net

With the addition of the G-Force model, a two-row three-point mounted on tracks, Univerco now offers a complete range of carrot harvesters. From the Mini-Veg that can be operated by a 60-hp tractor all the way up to the MAC Series of multiple-row, self-propelled and everything in between, Univerco can propose a solution for all needs and farm sizes.

The G-Force is unique in its category because it offers a compact, multiple-row, high performance machine, with a motorized track that will power it through the most difficult field conditions, at a much lower price than a self-propelled machine. State-of-the-art technology supports a user-friendly machine made to work every day for carrot growers.

Vogel Engineering Inc.

Custom-Built Harvesting Equipment

vogel-engineering.com

Made in the U.S., Vogel Engineering harvesters offer features such as a precision computer-controlled planting population system and individual row head height adjustability. Plus, the company offers a new Extreme Super Cleaning System.

Harvesters are available in two-, three-, four-, six- and eight-row configurations. Other available options include conventional roller bars or high-speed crowning.

Volm Companies

Packing Equipment and Packaging

volmcompanies.com

Volm specializes in providing expert solutions for the carrot industry, offering a range of equipment specifically designed for efficient carrot packing. Automating a carrot packing facility can decrease labor expenses while increasing production. Volm’s weighers and baggers are engineered to seamlessly integrate into any packing line, ensuring a smooth and efficient operation.

Volm also offers end-of-line solutions with a complete line of palletizers and case packers. In addition to equipment, Volm offers packaging supplies including poly bags that help lock in moisture and prevent unnecessary food waste. -

WSU Researcher Inducted Into Ag Hall of Fame

Tim Waters, a Washington State University (WSU) regional vegetable specialist, has been inducted into the Mid-Columbia Agriculture Hall of Fame. Hall of Fame members are recognized for their noteworthy achievements, expertise, and legacy of impactful results. Waters received the Rising Star Award, which recognizes demonstrated commitment to the future of agriculture.

Waters specializes in integrated pest management of carrot, potato, onion, dry bean and other production vegetables in the region, working closely with growers and crop consultants to address pest and disease issues they are experiencing. He has been a WSU faculty member since 2006.

-

Redox Turns 30

Redox Bio-Nutrients is celebrating its 30th anniversary this year. The company provides carbon-based nutrition products with bio-stimulant properties to agricultural producers across the U.S. and internationally. The company aims to help growers succeed in four primary areas: soil health, root development, abiotic stress defense and nutrient efficiency.

According to Redox, the field of bio-nutrition is gaining broad acceptance, and new breakthroughs in scientific research indicate a bright future for progressive growers. The company points to quantifiable benefits from bio-stimulants, including improved size and firmness for multiple crops, as well as dramatic nitrogen efficiency gains while maintaining strong crop yield.